The Importance of Using Caps and Plugs in Industrial Applications

In the bustling realm of industrial production, the smallest components can often have a significant impact on efficiency, safety, and operational costs. Caps and plugs, though seemingly inconsequential, play a pivotal role in maintaining the integrity of equipment and systems. They protect against contamination, damage, and even facilitate complex manufacturing processes.

Understanding the Role of Caps and Plugs in Industrial Settings

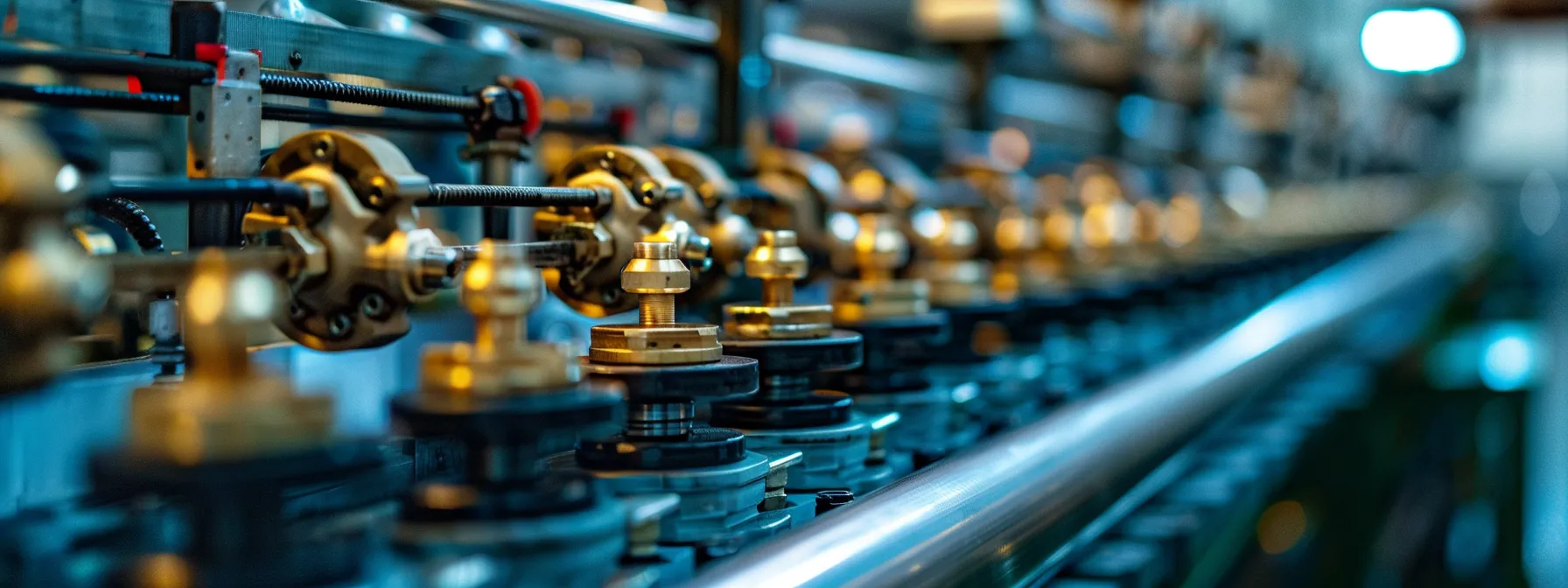

Caps and plugs serve a fundamental purpose in industrial environments by safeguarding machinery and components from external elements. These essential items are used to cover the open ends of pipes, tubes, hoses, and other conduits to prevent the ingress of contaminants such as dirt, dust, and moisture. By doing so, they ensure that the inner workings of machinery remain unobstructed and free from potentially damaging substances.

Not only do caps and plugs protect against contamination, but they also play a role in preserving the safety of personnel. By capping off sharp edges and exposed ends, they help prevent workplace accidents and injuries. Furthermore, during maintenance or shipping processes, these protective components keep essential oils and chemicals contained, reducing health risks and environmental harm.

Moreover, the right selection of cap plugs can enhance the aesthetics of final products, conceal internal components, and provide a clean finish to manufactured goods. Industrial caps and plugs come in a variety of materials such as plastic, metal, and rubber, each suited to different applications and environmental conditions.

The versatility of caps and plugs extends to their functionality during pressure testing. They can be used to seal systems temporarily, enabling accurate testing of components under operational conditions. This ensures that machinery and equipment meet the necessary safety and performance specifications before being deployed in the field.

Ensuring the Integrity of Equipment and Machinery with Protective Components

The use of caps and plugs is instrumental in extending the life of industrial equipment and machinery. By protecting critical components during processes such as painting, blasting, or coating, they prevent clogging, abrasion, and other forms of wear and tear that could compromise performance over time. These small components effectively seal out harmful elements that can accelerate the degradation of machinery parts.

In highly sensitive equipment, precision is key. Caps and plugs ensure that sensitive areas are shielded from particulates that could affect the accuracy and functionality of instruments. In industries such as aerospace, automotive, and electronics, where precision is paramount, reliable protection is integral to maintaining the exacting standards of production and operation.

Maintaining the structural integrity of pipes, tubes, and various openings during the manufacturing and assembly process is another critical aspect of protective components. By using caps and plugs, workers can ensure that internal passages stay perfectly formed and free from deformation, which could otherwise impact the flow of fluids or gases within the system.

The inevitable downtime that accompanies equipment maintenance and repair is also mitigated by using caps and plugs. By keeping components sealed and secure, these protective measures reduce the frequency and extent of maintenance required. They thus assist in avoiding costly interruptions to production schedules and contribute to the overall reliability of industrial operations.

The Benefits of Caps and Plugs for Cost-Effective Maintenance

Financial efficiency is a top priority in any industrial setting, and caps and plugs contribute directly to cost-saving measures. By minimizing contamination and damage, these small parts reduce the need for expensive repairs and replacements. This preventive approach enables businesses to allocate their financial resources more effectively and avoid unforeseen expenses.

Investing in high-quality caps and plugs also translates into longer-lasting equipment. By shielding machinery from environmental stressors and the rigors of continuous operation, protective components effectively slow the wear and tear process. This extended lifespan of equipment allows companies to maximize their investments in heavy machinery and other assets.

In the realm of preventative maintenance, caps and plugs are unsung heroes. Their role in facilitating easy inspection and quick servicing keeps maintenance routines streamlined and efficient. The ease of applying and removing these components saves valuable time and effort for maintenance personnel, who can then focus on more complex tasks.

Also, the cost-effectiveness of using caps and plugs extends to storage and handling. Many industrial components and equipment are stored for extended periods, and protective caps and plugs ensure that they remain in optimal condition until needed. This eliminates potential waste and the need to repurchase or refurbish items due to improper storage conditions.

Altogether, the strategic use of industrial caps and plugs demonstrates profound benefits for equipment longevity, cost savings, safety, and environmental compliance. These small yet vital components are pivotal in creating a more efficient, responsible, and sustainable industrial landscape.